Two Worlds, One Digital Future

Imagine walking through a modern power plant or a massive factory floor. Machines are humming, conveyor belts are rolling, and control panels are flashing. It looks mechanical, but behind it all, software is quietly running the show. That’s Operational Technology (OT) in action.

Now picture your office: emails, business software, cloud files, and servers keeping everything connected. That’s Information Technology (IT), the digital side of business.

These two worlds rarely met over the course of decades. OT lived in factory rooms; IT lived in server rooms. But in today’s world, with the rise of automation and the connected world, they are converging and becoming one powerful system. This IT-OT convergence is reshaping industries and introducing mission-critical cybersecurity challenges.

What is Information Technology (IT)?

Operational Technology (OT) controls the material aspect of operations. The technology is what monitors and controls industrial equipment, production lines, utilities, and infrastructure.

ICS, SCADA systems, PLCs, DCS, sensors, and robotic arms, etc., are all parts of OT environments. They ensure that the right level of pressure, temperature, or voltage level is maintained to ensure safe and efficient operations.

IT makes sure that your office does not lose its internet connection; OT makes sure that your factory, refinery or power grid does not stop.

Traditionally, these systems were air-gapped to be safe. But with the digitalization of the companies, OT is currently getting connected to the IT systems, bringing both new efficiencies and new vulnerabilities.

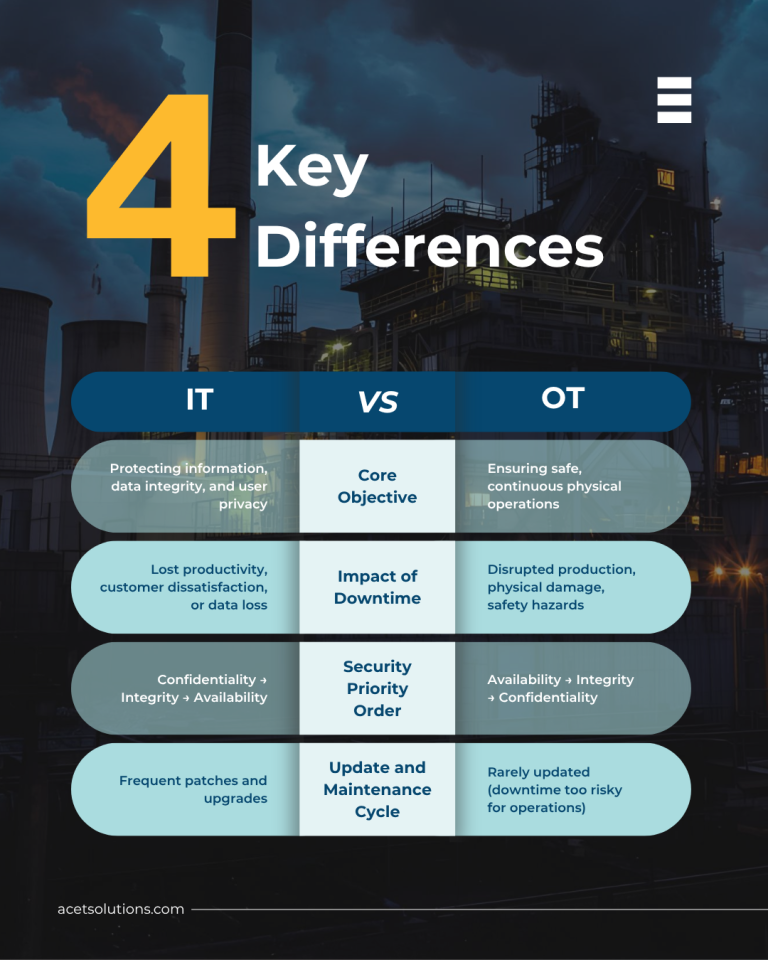

Key Differences Between IT and OT Security

Though IT and OT now intersect, their security priorities and risk profiles remain very different.

IT teams worry about data breaches, while the OT engineers worry about the closure of plants or equipment failures.

Malware in the IT sector may destroy files, but in OT, it may put a power plant out of business or halt the water supply of a city.

And that is the actual difference: one protects information, and the other protects lives and infrastructure.

Why IT and OT are Converging: The Drive for Smart, Connected Operations

The trend of digital transformation is erasing the border between IT and OT. Organizations have become interested in gathering real-time information from machines and using it as insights to improve their business.

In response to this, IT and OT are converging to have smart analytics, remote visibility, and operational intelligence. For example, power grid operators can control and optimize the flow of energy remotely throughout the cities.

Such convergence enables industries to run on a more efficient, agile, and predictive basis.

5 Benefits of IT-OT Convergence

The outcome of cooperation between IT and OT is game-changing. Here are five key benefits:

- Smarter Decision-Making

Integration of machine information and business analytics gives the leaders an entire real-time picture of the operations so that they can make quicker and smarter decisions. - Predictive Maintenance

Connected systems anticipate failures before they occur, instead of machines breaking down and wasting time, money, and stress. - Operational Efficiency

Automated insights enable streamlining of workflow, less energy usage, and less human error. - Cost Optimization

Companies save on downtime, maintenance, and wastage by combining the efficiency of the data with automation. - Unified Collaboration

IT and OT teams that were separate are now collaborating in terms of goals, information, and plans. This conformity brings secure and efficient operations.

IT-OT convergence makes information act and converts industrial processes into smart ecosystems.

4 Risks of IT-OT Convergence

- Cyberattacks on Critical Systems

After OT is linked to corporate or cloud networks, they can use vulnerabilities and access or incapacitate physical systems.

When IT and OT systems begin communicating, they create possibilities where none existed previously. Formerly isolated and secure industrial environments now have networks with business computers, emails, and even cloud applications. The existence of that connection makes it easier to work through the system.

In some cases, all that is required is a phishing email or an unpatched laptop. Once they are in, they can manipulate your OT system to hijack machines, switch off safety switches or even go to the extent of halting production. In industries such as energy, manufacturing, and utilities, real-life damage is possible due to such an attack. This is why establishing digital relationships creates strong defensive barriers as well as walls, such as network segmentation, access control, and 24/7 security, so efficiency is not sacrificed at the expense of protection.

2. Safety and Human Risk

Once a cyberattack strikes an industrial control system, it is not only data that is at stake, but also human lives. Suppose you have a system that regulates temperature or pressure, and it is hacked and causing it to lose its balance. Even a minor modification might cause fires, explosions, or even loss of an entire plant or facility.

Cybercriminals do not necessarily target individuals to hurt them but once they mess with automated controls, the outcomes might be risky and uncontrollable.

These systems have never been as vulnerable as they are now, thanks to IT-OT convergence. This is why securing them is not only an IT task, but also a safety mission. Checks and safeguards must be implemented with every new connection or automation step to ensure that technology does not ever harm human safety.

3. Operational Downtime

Even an hour of downtime in manufacturing or an energy industry can result in millions of loss and a damaged reputation.

In industries where every second counts, an hour of system offline seem like a catastrophe. When IT and OT networks are interconnected, one cyber-attack may shut down entire production lines, halt shipments, or stop energy flow. This not only means loss of money but can also affect the reputation of the company and destabilize customer trust.

A network glitch, a ransomware attack or even a minor misconfiguration will rapidly escalate into hours or days of non-functioning. Visibility and preparedness are the key to prevention. Industries must understand and have visibility of their assets, know how those systems are interrelated, and how they can be reinstated in time in case anything is wrong. Because in the world of OT, a few minutes of prevention can save millions in recovery.

4. Legacy Systems and Poor Visibility

A lot of factories and industrial plants are still operating on systems that have been designed long before cyber threats were developed. These legacy systems are reliable, but they weren’t designed to handle modern cybersecurity challenges and cannot be updated, patched, or safeguarded using new tools, making them an easy target.

When these obsolete systems are connected to newer IT networks, the risks are increased. What’s worse, many organizations lacks complete visibility into all devices that are operating in their OT environment. Without this awareness, knowing what you have on your network, where it is vulnerable and how to protect, responding to threats becomes difficult. You cannot protect what you cannot see, and visibility is the basis of all secure operations.

Examples

The Colonial Pipeline cyberattack in May 2021 served as a wake-up call for the world. What started as an intrusion into the IT systems of the pipeline eventually trickled down into serious real-world consequences, including fuel shortages, price surges, panicked drivers, and emergency declarations across 17 states.

The hackers gained access via a breached VPN account that lacked multi-factor authenticated (MFA).

Although the attack was mainly in the IT systems, the threat to the OT systems forced Colonial to close down the pipeline altogether for six days. This cut off of flow immediately caused fuel supply disruption in the East Coast. The results was long lines at gas stations went out, the average prices in the affected areas increased by approximately 4 cents per gallon, and emergency measures were put in place by the federal and state governments to contain the situation.

That’s why securing both environments, IT and OT, is no longer optional – it’s mission-critical.

Future of IT and OT: Secure and Intelligent Industrial Era

With the advancement of technologies, the integration of data and devices will be even more profound.

We’re heading to the world where:

- AI prevents and predicts failures in the system before humans realize them.

- Digital twins replicate real-life functions to reduce risk.

- Cloud and edge networks provide insights in real time.

But these future requirements are robust and organizations will need to invest in:

- Network segmentation (to isolate OT from internet-facing systems)

- Zero Trust architectures (to verify every access request)

- Cyber awareness training for both IT and engineering teams

The industries that master this balanced speed and safety, innovation, and protection will define the next industrial revolution.

Conclusion

IT and OT used to be two sides of different worlds, digital and physical. Today, they’re two halves of the same heartbeat driving modern business. Their convergence brings immense value: efficiency, intelligence, and innovation. But it also calls for a shared responsibility to protect systems that power our lives. Because when data and machines unite securely, industries don’t just operate – they evolve.

The future isn’t IT or OT. It’s both: connected, intelligent, and secure. To learn more about how we’re enabling secure industrial transformation, visit our website.

Frequently Asked Questions (FAQs)

The hardware and software used to manage and monitor physical steps and devices within the industry.

IT is involved in data management and security, whereas OT oversees the machine and operation control and protection.

Since industries require real time visibility, predictive maintenance and integration of control, which are achieved by linking information systems (IT) to operational systems (OT).

OT is critical in manufacturing, energy, utilities, oil & gas, mining, healthcare, transportation, and infrastructure.

Because a cyberattack on OT not only steals data, but it can also shut down production, put lives at risk, and interfere with national infrastructure.

Related Articles